3D Print

Here you can read about 3D printing and see some of what we have made

The History behind 3D Printing

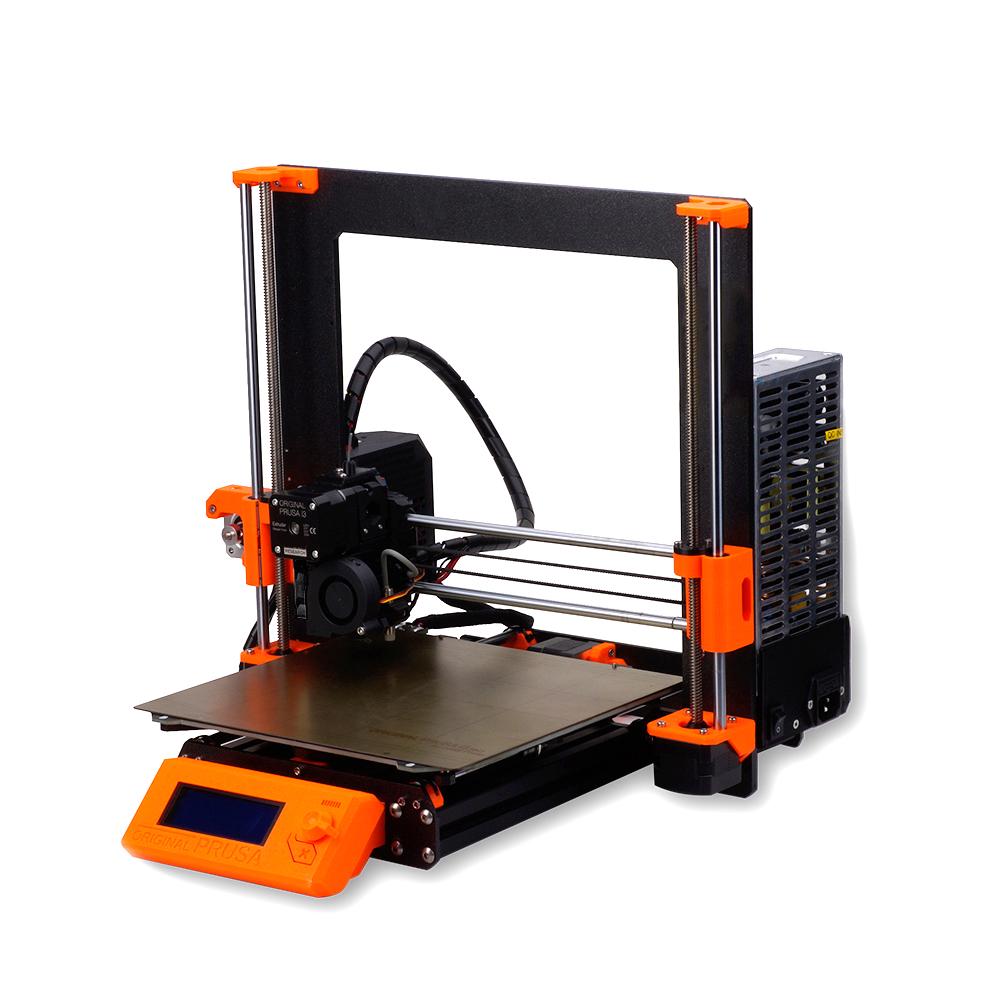

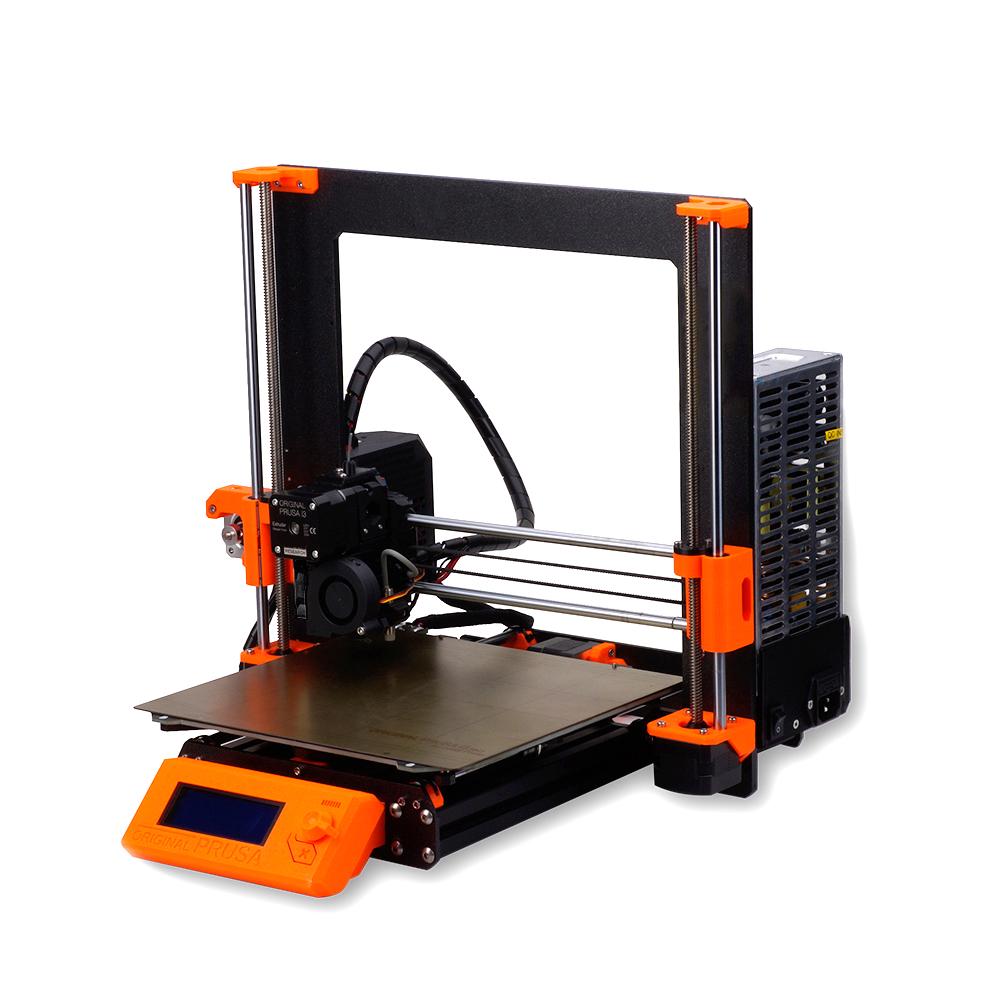

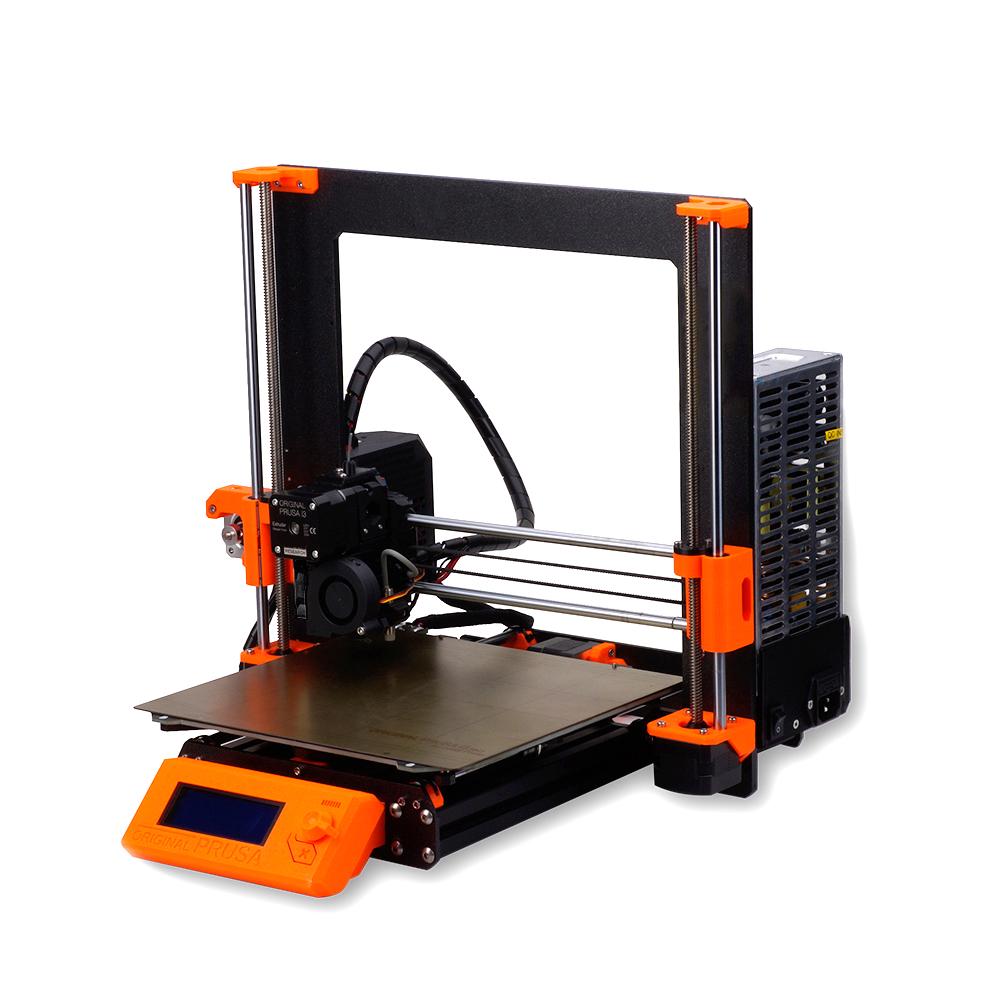

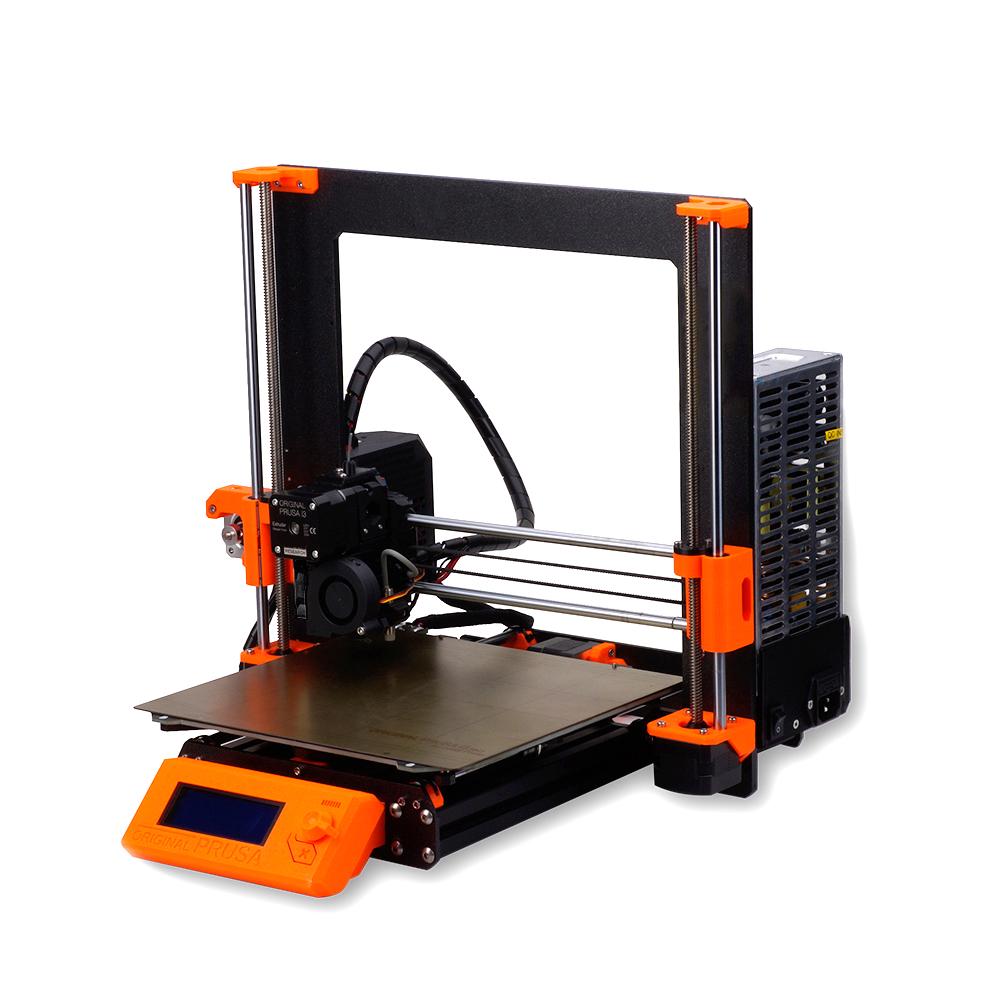

3D Printing uses additive manufacturing and is a technology that enables the construction of a three-dimensional object from a CAD model or a digital 3D model. The term “3D Printing” can refer to any number of processes in which material is deposited, or solidified under control of a computer to a three-dimensional object, with material being layered together (such as various types of plastic, liquids or powder grains that are fused together), usually layer by layer.

In the 1980s, 3D printing technology was only considered to be suitable for the production of functional or aesthetic prototypes of goods, and a more appropriate term for the technology at the time was rapid prototyping. Per in 2019, the precision, repeatability and range of the material types for 3D printing have improved to such an extent that 3D printing processes are considered viable as an industrial production technology, whereby the term additive manufacturing can be used synonymously with 3D printing. One of the main advantages of 3D printing is the ability to produce very complex shapes or geometries that would otherwise be impossible to construct by hand, including hollow parts or parts with built-in masonry structures to reduce weight.

Materials that can be printed with

The most widely used 3D printing material is thermoplastic, but there is a very long range of other materials that can also be used for 3D printing:

Printers within the “Material Extrusion” category can print with thermoplastics such as PLA, PETG, ABS, Nylon, Polycarbonate etc., living cells, food, cakes, cement, clay, medicine etc. It is also quite common to use thermoplastics mixed with carbon fibre, seaweed, glass fiber, wood fiber, types of grass, metal powder, and generally residual products from various forms of production, for example hops from beer production, sugar cane, coffee, hemp, soya, etc.

“Powder Bed Fusion” and “Directed Energy Deposition” print in metals such as steel, stainless steel, aluminium, copper, gold, platinum, silver, palladium, tungsten and niobium. “Sheet Lamination” 3D printers print in paper and metal foils. The liquid that “Vat Photopolymerization” printers print in is liquid photopolymer resin, which is toxic to work with, viscous and quite expensive. The thing that is printed has a nice finish compared to other 3D printing technologies, but the finished printed object must be post-cured in the sun, but still they are quite porous, and as such not suitable as mechanical parts.

Sustainability

Most types of 3D printing use relatively much energy compared to traditional production methods, because they work e.g. to melt filament or with compounding powder material with powerful laser. On the other hand, with 3D printing, you can often produce parts that use far less material than similar parts produced traditionally, which in many cases will offset the higher energy comsumption per lot.

In addition, there are a number of advantages that 3D printing has due to its great flexibility. For example, it does not require any tools to produce a component with 3D printing, as it e.g. does with injection molding, which gives 3D printing a major sustainability advantage for smaller productions. Spare parts that may not have previously been able to be put into prodution will, with 3D printing, require a much smaller investment, which can extend the lifetime of other products.

Because 3D printers can produce many different things, a single 3D printer can replace several machines in a production and make factories smaller. In addition, it makes it easier to place 3D printers in several places, so that transport needs are reduced. In combination with the fact that you can more easily adjust production as needed, 3D printing also reduces the need for inventories.

Because it is easy and cheap to produce individual parts, 3D printing also makes it easier to tailor components for their precise application. Thereby you can get better components and products, which further contribute to the sustainability of 3D printing. However, 3D printing generates a relatively large amount of waste, which is difficult to recycle. Both support material, misprints and unused filament, powder or resin are sources of waste. In 3D printing that uses powder as material (e.g. SLS), all the non-sintered material immediately becomes waste, but a company has now achived 100% recycling.

Constuction

Large cement 3D printers have started to be used in house construction. The 3D printers are assembled on the construction site and can then print the walls of the house. The aim is partly to be able to build houses more efficiently and cheaper, but also to reduce the amount of waste. The company Might Buildings claims that with 3D printing they can build twice as fast, with 95% less work time and 10 times less waste than with conventional construction. In Amsterdam, 3D printing has been used to produce a bridge in one piece.

Aviation

With 3D printing, you often produce parts with far less material consumption than you can with traditional production methods, which makes it suitable for the aviation industry, where even a small weight reduction can result in large fuel savings. It is estimated that 3D printing can make commercial aircraft around 7% lighter.

Applications

3D printing is still growing rapidly and so is the use of the technology. In the beginning, the primary use was design, visualiztion, mock-ups and prototypes- But gradually there are more examples of 3D printing in mass production, or for the prodution of spare parts. it can take serveral weeks from the order a for spare part to a military tank arrive, and the price of such things is often astronomical, so there are stories that the US military has 3D printers of the types “Powder Bed Fusion” and “Directed Energy Deposition” standing, to make spare parts if they have to improvise and dont have time to wait for new ones from a factory.

Recently, the use of 3D printing technology has been suggested for artistic expression, the artist Bathsheba Grossman uses various 3D printed prototypes in many of her works.

3D printing technology is currently being reserached at biotechnology companies and universities, and the use of 3D printing for printing out organs and body parts well advanced. When a 3D printer of the “Material Extrusion” type prints an ear, layers upon layers of living cells are placed on a jelly medium which is slowly built up to form the ear or other 3D structures.

Printers in the categories “Powder Bed Fusion” and “Directed Energy Deposition” are used by industries such as the automotive industry, shipyards, in the military, in aircraft production and for the production of aerospace equipment.

Printers in the “Vat Photopolymerization” category are used by dentists and jewelers.

Resolution or Voxels

When we talk about printing in 2D and about screenshots, it is relevant to talk about resolution, but when talking about 3D printing it does not make so much sense:

In 2D printing, the success criteria are that the resolution is so high that you cannot see the image points (pixels) and it is less important to control micrometers exactly how big an image is on the paper. With 3D printing, It’s the other way around: The resolution is almost irrelevent, as long you have 100% control over the size of the printed object.

Most 2D printing is bitmap or pixel graphics, while most 3D printing is vector-based.

However, there are some manufacturers of 3D printers that talk about resolution, but here a distionction is made between layer thickness (z-axis) and X-Y resolution in Dot Per Inch (dpi). Layer thicknesses are between 300 micrometers (0,3 mm) and 0,05 mm. The X-Y resolution is comparable to that of laser printers. The particles (3D dots) are about 50 to 100 micrometers (0,05-0,1 mm) in diameter. Very few 3D printers state X-Y resolution in dpi, as this only applies to 3D printers that use a technology comparable to 2D printers. FDM printers, such as Stratasys* Dimension, work vector-based, where the dpi specification is not relevant.

Detailed history of 3D printing and more

- The 1980s

- Many people think that 3D printing is relatively new technology, but the 3D printer was actually invented already at the beginning og the 1980s. Thus, it was Hideo Kodama from the Nagoya Industrial Research Institute in Japan who in 1981 was the first to develop an additive production unit of the “vat photopolymerization” category. The first commercialization of 3D printers was the company Stratasys, when in 1988 they used the rights to their owner S. Scott Crump’s FDM 3D printer technology. Stratasys’ 3D printer first entered the marked in 1992 and had limited success due to its high price and technological limitation.

- The 2000s

- New versions of Stratasys’ FDM 3D printers had greater market success and in 2003 they were thus the best-selling rapid-prototyping technology. In 2003, the patent on SLA-Stereolithography also expired. The RepRap project was started by Adrian Bowyer at the University of Bath, Where he and his fellow student wrote an assignment about a self-replicating machine, which was later called RepRap (Rapid Replication). It is released under the GNU license. In 2009, the patent on Stratasys’ FDM technology expired. ASTM’s Aditive Manufacturing F42 Standardization Project was also initiated and MakerBot Industries opened, launching the first commercial open source 3D printer, the MakerBot Archived November 11, 2020 at the Wayback Machine.

- The 2010s

- In 2014, Denmark’s first professional business for 3D printing, 3D Printhuset, was opened in Copenhagen. In 2017, Denmark’s first house was printed in Copenhagen.

- More about Resolution and Voxels

- If you do a google search for “3D printing” combined with “resolution”, you will probably come across the term “A Voxel” which is a three-dimesionnal pixel. The problem with using this expression is that it does not take into account that there is difference between the dimensions in the z axis and the x-y axes.- It would be beautiful concept in a perfect world, where a 3D printer was just a laser printer that printed in 3D, but unfortunately it is not that simple.